Hey Doug, Keith, and Fordman, thanks very much for replying!

Doug Comer wrote:I put a set of R&M looms that go under the valve cover on mine. Got them from Summit, about 50 bucks. I like them with the wires that you have to put the ends on(can't think of the name

). The wires are 8mm MSD. If you like I can try to get a pic.

Doug, thanks for letting me know about this option! I think the methods I've come up with so far will work out OK for me. The way the wires are kept together now, with those funny chrome clamps on the wires themselves, kind of holds it together. I'm just trying to make them look better at this point.

Now that I know about this, I'll remember to ask you for photos if I want to go that route! Thanks!

Hey Keith! I read the post and it's very interesting! I'm not sure how important it is for me to keep my wires separate, since they're brand new, high end Taylor wires. It's funny that Proformance Unlimited (they installed them) put them on using tie wraps. For significant lengths of wire around the alternator, all four wires for one side of the engine are tightly coupled together using tie wraps!

That makes it look very tidy, but it makes me wonder about whether I should really pull them apart.

Keith, do you think it's worth the effort to pull the wires apart even if I'm using brand new Taylor 8MM wires? Thanks!

fordman wrote:dont run them through the gas tank.

This I will try to avoid! Thanks for the tip Fordman!!!

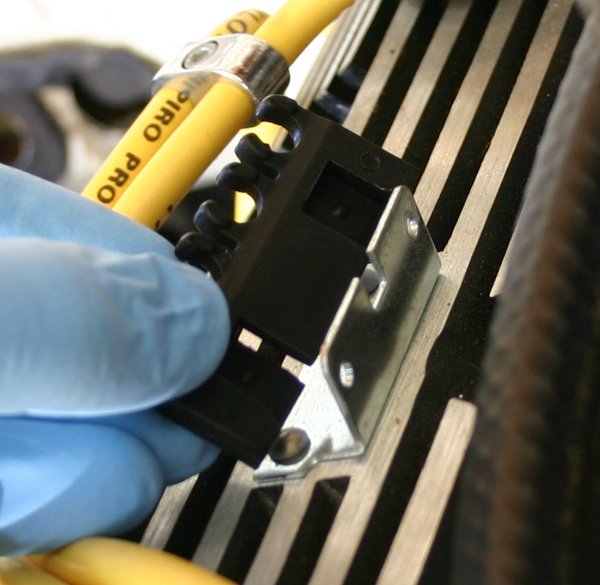

So the looms (moose antlers) recommended by Robert arrived, and they look great!

There were little plastic bumps molded in to the looms that matched up perfectly with the holes in the valve cover loom mounts.

I pressed one of the 8MM wires in to it, and they do fit, although it's a very tight fit. I'm not sure how smart it is for me to be squishing the insulation on the wires that hard! So I'm not sure if I'll wind up using these looms or not. I might try to enlarge the holes somehow to make the fit more easy going.

Thanks very much for all the superb advice!

Robroy